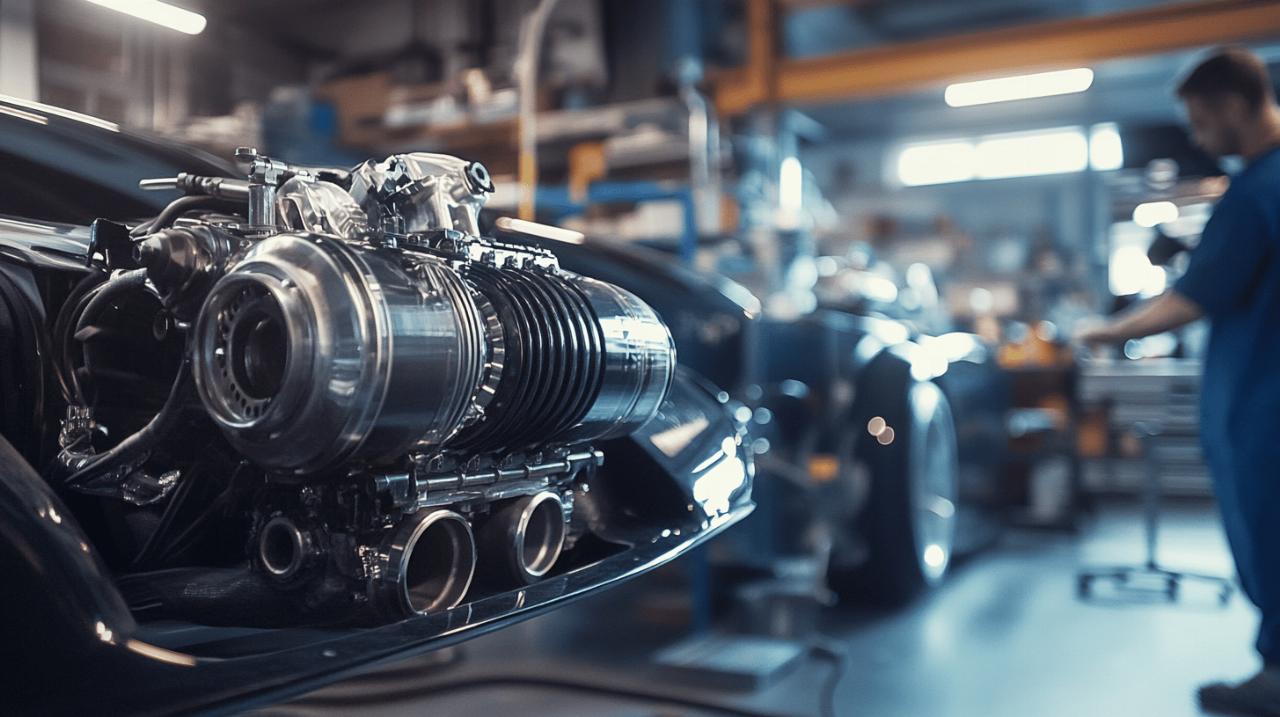

Turbochargers significantly enhance engine performance, but they require dedicated maintenance to operate efficiently and quietly. Whistling noises from your turbo aren't just annoying – they're warning signs of potential issues that could lead to costly repairs. This comprehensive guide will walk you through essential maintenance practices to keep your turbocharger running smoothly and prevent those telltale whistling sounds that indicate trouble.

The importance of proper lubrication

Proper lubrication stands as the cornerstone of turbocharger health. Turbochargers operate at incredibly high speeds – often exceeding 150,000 RPM – and generate extreme temperatures. Without adequate lubrication, the delicate components within the turbo will experience excessive friction, leading to premature wear and that distinctive whistling noise. As highlighted by auto-service-gall.de, oil starvation represents one of the primary causes of turbocharger damage and subsequent failure.

Scheduling regular oil changes

Maintaining a strict oil change schedule is non-negotiable for turbocharger health. Unlike naturally aspirated engines, turbocharged engines place additional demands on engine oil due to the higher operating temperatures. Most manufacturers recommend changing oil every 5,000 to 7,500 miles for turbocharged vehicles, though this interval may decrease in severe driving conditions. Fresh oil ensures proper viscosity and cleaning properties remain intact, protecting your turbo bearings from wear that could lead to shaft play and whistling.

Selecting the Right Oil Type for Your Turbocharger

Not all engine oils are suitable for turbocharged applications. Manufacturer-approved synthetic oils with appropriate viscosity ratings provide superior protection against the extreme temperatures turbochargers generate. These specially formulated oils maintain their lubricating properties even when exposed to the intense heat of the turbo system. Using inferior oils can lead to coking, where oil bakes onto turbo components, restricting movement and creating noise. Always consult your vehicle manual for the specific oil grade recommended by Essex Turbos or your vehicle manufacturer.

Air filtration system maintenance

The air filtration system directly impacts turbocharger performance and longevity. Clean air entering the system prevents abrasive particles from damaging the precision-balanced compressor wheel, which spins at tremendous speeds. Even minor damage to this component can create imbalance, resulting in whistling noises and reduced performance.

Signs of a Clogged Air Filter

A clogged air filter restricts airflow, forcing the turbocharger to work harder to achieve the same boost pressure. This additional strain manifests as decreased engine performance, reduced fuel economy, and potentially unusual noises including whistling. Modern vehicles might trigger a check engine light when airflow sensors detect restricted intake. Regular inspection reveals visible dirt accumulation, discoloration, or an inability to see light through the filter material when held up to a bright source.

How to Properly Clean and Replace Air Filters

While some air filters can be cleaned, most modern vehicles use disposable filters that require replacement at regular intervals. For replaceable filters, ensure you purchase high-quality components that meet manufacturer specifications. During replacement, inspect the air box for debris and clean it thoroughly. Check all connecting hoses and clamps for secure fitment, as loose connections can create air leaks that produce whistling sounds. Most manufacturers recommend air filter replacement every 15,000 to 30,000 miles, though dusty environments necessitate more frequent changes.

Inspecting hoses and connections

The turbocharger system incorporates numerous hoses and connections that transport pressurized air throughout the engine. Any leak in this network can create the distinctive whistling noise while simultaneously reducing performance. A comprehensive inspection of these components forms an essential part of turbocharger maintenance.

Common leak points in turbo systems

Several areas are particularly prone to developing leaks in turbocharged engines. The intercooler connections, where pressurized air travels between the turbo and intake manifold, frequently develop issues due to the pressure fluctuations they experience. Additionally, the wastegate actuator hoses, vacuum lines, and intake manifold gaskets represent common failure points. Even small cracks or loose clamps can produce noticeable whistling under boost conditions while robbing your engine of precious performance.

Tools and Techniques for Leak Detection

Identifying boost leaks requires methodical testing rather than guesswork. Professional mechanics often use smoke machines that pump visible vapor through the system, making leaks immediately apparent. For home mechanics, a mixture of soapy water applied to suspected leak areas while the engine runs at higher RPMs can reveal escaping air through bubbling. Listening devices help pinpoint the exact location of whistling noises. For comprehensive testing, pressure testing the entire system provides definitive results, though this typically requires specialized equipment available through automotive service centers.

Turbocharger component examination

The internal components of the turbocharger itself require regular inspection to identify potential issues before they develop into serious problems. Whistling often originates from worn or damaged parts within the turbo assembly, making periodic examination crucial for preventative maintenance.

The internal components of the turbocharger itself require regular inspection to identify potential issues before they develop into serious problems. Whistling often originates from worn or damaged parts within the turbo assembly, making periodic examination crucial for preventative maintenance.

Visual Inspection of Compressor and Turbine Wheels

Examining the compressor wheel requires removal of the intake pipe leading to the turbo, providing visual access to this critical component. Look for signs of damage including chipped or bent blades, foreign object impact marks, or excessive dirt buildup. The turbine wheel, located on the exhaust side, proves more difficult to inspect without partial disassembly. However, a borescope camera inserted through the exhaust connection can reveal damage or carbon deposits that might affect balance and create whistling noises. Any signs of wheel damage typically require professional attention from specialists like Toowoomba Superior Turbos.

Identifying shaft play and bearing wear

Excessive movement in the turbocharger shaft indicates bearing wear, a common cause of whistling noises. Testing for shaft play requires gently pushing the compressor wheel sideways and observing any movement. The acceptable tolerance is minimal, typically less than 0.1mm. Any significant movement suggests bearing deterioration requiring immediate attention. Oil leaking from the turbo housing also indicates seal failure, often resulting from bearing wear. These issues necessitate professional evaluation as bearing replacement involves complex disassembly beyond most home mechanics' capabilities.

Complementary engine maintenance

The overall health of your engine directly influences turbocharger performance and longevity. Neglecting basic engine maintenance creates conditions that place additional stress on the turbocharger system, potentially leading to premature failure and whistling noises.

How engine health affects turbocharger performance

Engine issues such as carbon buildup, faulty fuel injectors, or ignition problems create uneven combustion that impacts exhaust gas flow through the turbine. This irregular flow pattern stresses the turbo components and can contribute to whistling noises. Additionally, engine oil quality affects turbocharger lubrication, while cooling system problems may cause excessive heat buildup that damages turbo seals and bearings. Maintaining proper engine tune ensures the turbocharger operates within its designed parameters, reducing wear and associated noise.

Preventative measures for engine-related turbo issues

Following manufacturer-recommended service intervals for spark plugs, fuel filters, and injector cleaning helps maintain optimal combustion. Regular cooling system maintenance, including coolant replacement and thermostat testing, prevents overheating that can damage turbo components. Additionally, proper warm-up and cool-down procedures allow oil to reach operating temperature before applying heavy loads and give the turbo time to cool gradually after high-speed operation. These simple habits significantly extend turbocharger life and prevent issues that manifest as whistling sounds.

Diagnostic approaches for turbo whistling

When whistling noises occur despite preventative maintenance, systematic diagnosis helps identify the root cause and determine the appropriate solution. Understanding the different types of whistling sounds and their likely sources guides this process.

Distinguishing between normal and problematic sounds

Modern turbochargers produce some noise during normal operation, particularly when boost builds rapidly. This normal sound typically presents as a smooth, consistent whooshing rather than a sharp whistle. Problematic whistling tends to have a higher pitch, varies with engine speed, and often becomes more pronounced under load. Whistling that appears suddenly likely indicates a developing issue, while sounds that have been present since installation might represent a design characteristic. Recording the sound can help when consulting with turbo specialists who can distinguish normal operation from concerning symptoms.

When to seek professional turbocharger service

While many maintenance tasks fall within the capabilities of enthusiast mechanics, certain situations warrant professional intervention. Persistent whistling despite addressing common causes, visible damage to turbo components, significant oil leakage from the turbo housing, or noticeable performance loss accompanied by noise all indicate the need for expert assessment. Companies specializing in reconditioned turbos like Essex Turbos offer comprehensive diagnostic services with specialized equipment to pinpoint issues accurately. Their technical expertise and access to replacement parts ensure proper repair without the risk of additional damage from improper disassembly or reassembly.